Low impact production

- Target: 100% use of low impact processes in our production by FY 26/27

- Progress: 20% of our collection is made with verified low-impact processes and over 70% of production is covered by our supplier environmental questionnaire in FY 23/24

If materials bring our products to life, their treatments and finishes give them attitude. At Acne Studios we love distressed textures, unique washes, unconventional colours, and experimental prints. But whether the product is monochrome or multicoloured, glossy or raw, we are exploring ways to create the right quality and patina with less impact. We have developed a low impact production guide to help our design team and suppliers reimagine style and sustainability, and with new dyes, treatments, and technologies, we are innovating ways to reduce the water, chemicals and energy used in our production processes. By FY 26/27, we will use verified lower-impact production processes across our collections.

Musubi by LWG

Our iconic black and brown Musubi bags are made using leather sourced from tanneries awarded a gold or silver medal by the leather Working Group (LWG). The LWG is a leading global initiative working to reduce the environmental impact of leather tanning. Around 70% of all the leather we use in our collections is sourced from tanneries rated silver or gold by the LWG, meaning they exhibit the highest standards in energy and water use, chemicals and wastewater.

Denim Washes

Acne Studios was born from denim, so ensuring our denim production is as clean as possible is a priority. We have developed a denim wash classification tool to reduce the water, chemicals and energy used in the washing and finishing of our denim. Based on the globally recognised Jeanologia methodology, our tool encourages our partners to use the latest in laser, nanobubbles and ozone technologies to achieve the same look and feel with a lighter environmental footprint. Today, around 50% of our denim meets our low impact wash criteria.

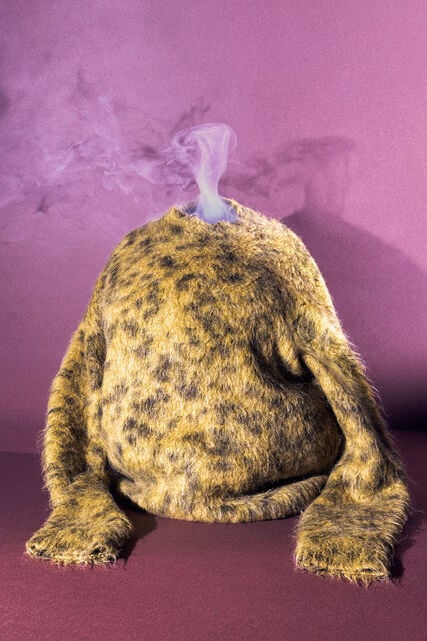

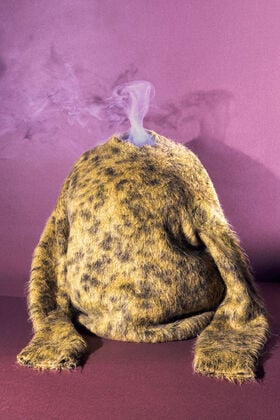

The Face Jersey

We are increasing our standards for low-impact production through our unisex Face collection. We are creating pieces using certified organic materials and processes from farm to finished product. This means that the dyes must meet the standards set out by the Global Organic Textile Standard (GOTS) throughout the entire supply chain. We are now working to expand these standards across our jersey/fleece range and for our denims.

More on Sustainability